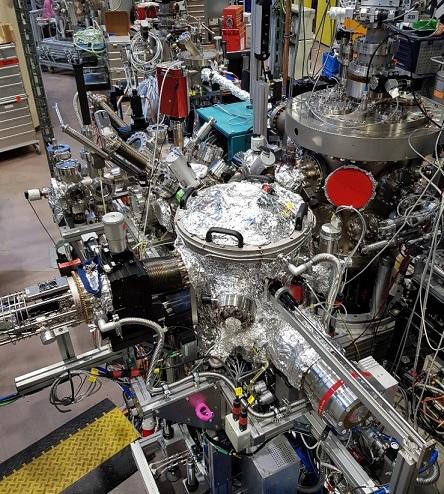

Molecular Beam Epitaxy and Magnetron Sputter Deposition chamber at PM3 beamline of BESSYII

Sample Growth

The investigation of ultrafast magnetic dynamics in 4f and 3d magnets, their multilayers and alloys requires high-quality and well-structured samples. To ensure the growth of suitable samples, we built up a highly-specialized sample growth unit, consisting of a Molecular Beam Epitaxy chamber and a Magnetron Sputter Deposition chamber at the synchrotron facility Bessy II, Berlin.

Molecular Beam Epitaxy

We are specialized in the growth of metallic thin films. One of the core techniques is Molecular Beam Epitaxy (MBE). Here a reservoir of material, the so called evaporant, is heated until it starts to evaporate. The evaporated material is guided onto a substrate and grows to metal films layer by layer. For a broad range of possible growth materials we deploy self-build evaporators and EFM3s. These use high voltage to accelerate thermionic released electrons onto a crucible filled with the evaporant or directly onto rods of evaporant. In addition, Knudsen cells are used, which can reach temperature suitable for evaporation by resistive heating. MBE is especially well suited to grow thin films of a few nm thickness and hence, combined with having multiple sources, is optimal to prepare multilayers or alloys. Our MBE chamber features six slots for different MBE-sources for growth and a quartz micro balance, a quadrupole mass spectrometer and a RHEED system for in-situ growth control. Further characterization can be performed in the X-ray scattering chamber deployed at the PM3 beamline, which is directly connected to our growth system, i.e., in vacuum transfer is possible.

Magnetron Sputter Deposition

For an even wider range of growable materials a high-vacuum chamber specialized for sputter deposition is available. Here a reservoir of material, the so-called target, is bombarded with Argon ions. The relatively large Argon ions destroy the surface of the target and the released material is guided onto a substrate, where it forms layers of the sputtered material. Sputter deposition enables much higher growth rate then MBE but generally leads to less well-structured films as MBE. Our sputter chamber is equipped with four different sputter sources, which can be worked in DC or RF mode. Additionally, reactive sputtering is possible.